Large-scale metal are subject to strict quality standards in the energy, aerospace, industry and defense markets. Defects or non-quality result in lost profits.

Traditional methods consume large amounts of energy and resources and have a high environmental footprint. They are not competitive or agile enough to build, repair or remanufacture high-value, low-volume parts.

With AMFREE Machine, manufacturing large metal parts becomes fast, cost-effective, and sustainable!

Turnkey hybrid machine, designed to improve productivity and industrial sovereignty, and easy to use by non-experts.

Patented technology

AMFREE One machine use a versatile robotic architecture, accessible to all industry players, particularly those involved in manufacturing large metal parts.

Digital chain

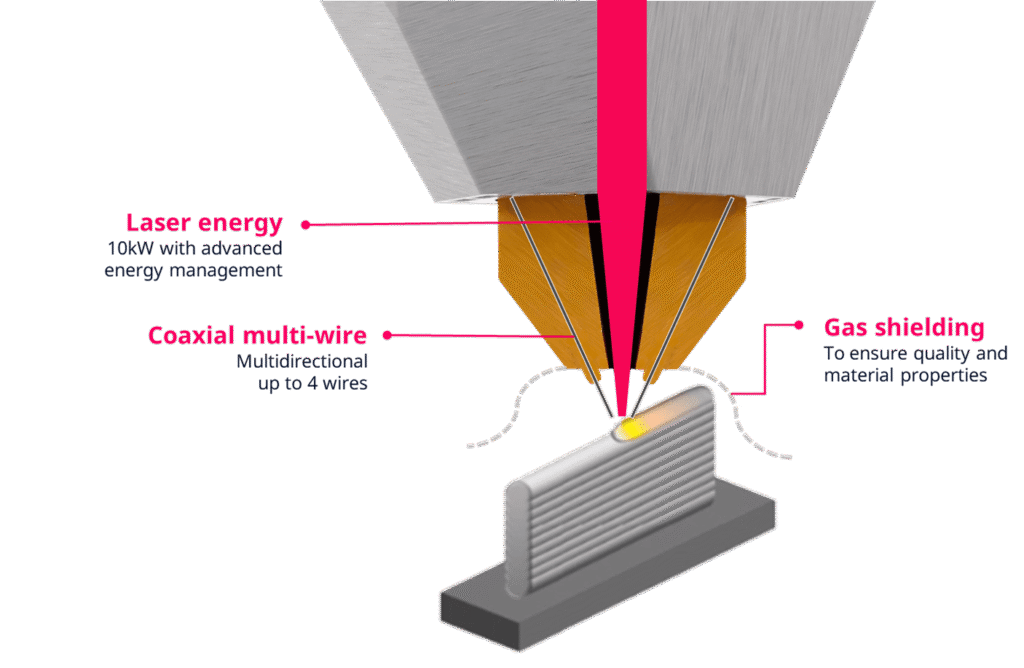

AMFREE patented industrial technology enables competitive high speed multi-directional deposition. Laser energy profile is adjustable to best match with material properties, ensuring extreme robustness, quality, and accuracy.

Service Center

AMFREE Service Center provides services that simplify and speed up the industrialization of new applications with the AMFREE machine.

Additive manufacturing reduces energy and material consumption, waste and pollution, helping companies reduce the global carbon footprint of large-scale metal manufacturing. Our machines are designed to produce sustainable repairable parts. It’s also possible to extend the life of existing parts, helping to build a sustainable and more resilient industry for the next generations. It’s enable waste reduction, by using a strictly limited amount of raw material.

All AMFREE machines opens a 60-month access to “Service Center”. It works to improve user experience, and guide you to use the best of AMFREE machines:

Most people forget additional hidden costs to use an industrial additive manufacturing machine and build qualified parts: CAD/CAM software, additive manufacturing specialists to set up new applications, additional sensors to monitor the process, tests to qualify new applications, complexity induced using non-standard software or home-made machines…

To avoid any hidden costs, AMFREE solutions are standardized and ready to be used by non-specialists, to guarantee first-time-good parts. All software and hardware provided are fully compatible (with each other) and allow the transfer of production from site to site, from user to user, with the same quality. You don’t need to be an expert to use an AMFREE machine, and the entire user experience is designed to make it easy for non-specialists to produce complex parts according to strict market standards.

The high productivity of the AMFREE machine enables production 2 to 20 times faster than other large-scale additive manufacturing technologies, including for multidirectional manufacturing. Designed to be robust for long cycles, laser multi-wire technology doesn’t require inter-layer temporization for most of the maretrial, and laser accuracy combined to a manageable track enable manfuracturing with reduced manufacturing offsets. High-speed thermomechanical simulation is used to de-risk manufacturing prior to fabrication. Unpredictable defects are directly controlled by process control during manufacturing to ensure the best and most consistent quality.

The laser melts the material continuously. Dynamic energy management ensures the best melting conditions for the specific material and deposition configuration. The high metallurgical quality of the laser process is now available for high volume production. Energy management and wire feed are managed independently, making the technology extremely robust. In addition, AMFREE technology has an ultra-wide operating window.

Work with our technical team to maximize your business.

2 simulate

3 build

4 control